The picture below belongs to 3M research division. The difference of 70 candela & 250 candela of the two types is clearly visible in the picture. After 7 years, the reflection value of Engineer Grade material decreases sharply but the reflection value of the High Intensity Grade after 10 years is even more than the reflection value of the Engineer Grade at start.

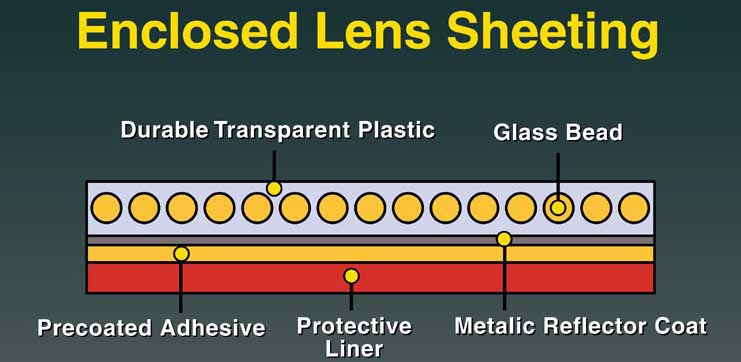

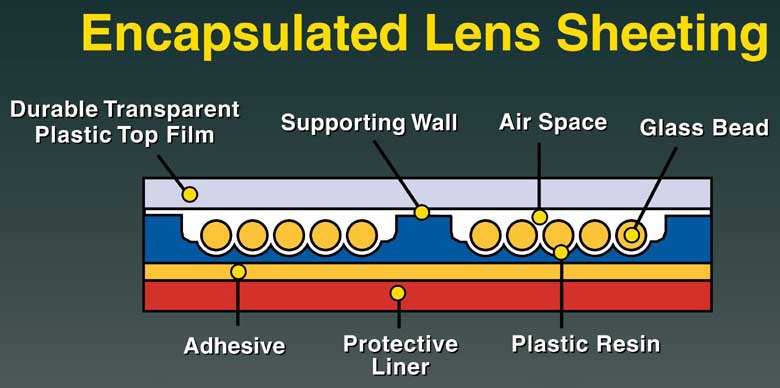

The conclusion is that using High Intensity Grade material is much better & more economical. It was mentioned earlier that these sheetings are composed of glass spheres. This is true for engineering & High Intensity Grade material but Diamond Gradeis composed of glass prisms.

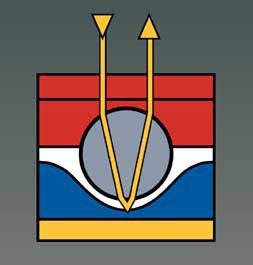

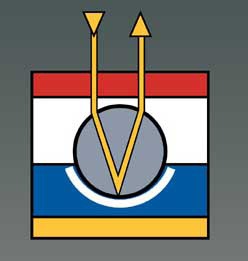

One of the differences between the engineering & High Intensity Grade material is that in the High Intensity Grade, glass spheres are confined in a multi – sided holder which causes less damage to the focal length & the back mirror, thereby increasing the life time of these sheetings.

informatory signs. Minimum reflection value of white sheets are 70 candelas at start & maximum usable life is 7 years. In other words white sheetings have less them 35 candelas reflection when their usable life is finished & this statistically happens in year seven but it should be noted that in areas with high occurrence of sand storms this life decreases, sometimes up to a half. Most of the existing signs in Iran and other countries have used this type of sheetings.

informatory signs. Minimum reflection value of white sheets are 70 candelas at start & maximum usable life is 7 years. In other words white sheetings have less them 35 candelas reflection when their usable life is finished & this statistically happens in year seven but it should be noted that in areas with high occurrence of sand storms this life decreases, sometimes up to a half. Most of the existing signs in Iran and other countries have used this type of sheetings.

This Type of sheeting is made of a composition of prisms in the High Intensity Grade along with fluorescent paints. This paint absorbs the low wavelength ultraviolet radiation of the sun (which is invisible) & reflects them with high wavelength visible rays. This causes the sign to be more clearly visible in limited lights (such as cloudy weather & start & end of the day). This also makes the sign visible from longer distances & the drivers have more time to react to the sign message. These sheetings are High Intensity fluorescent with minimum useful life of 10 years & minimum reflection value as per ASTM D4956 is defined for yellow color. The acceptable types are 3, 4, 7 & 8.

This Type of sheeting is made of a composition of prisms in the High Intensity Grade along with fluorescent paints. This paint absorbs the low wavelength ultraviolet radiation of the sun (which is invisible) & reflects them with high wavelength visible rays. This causes the sign to be more clearly visible in limited lights (such as cloudy weather & start & end of the day). This also makes the sign visible from longer distances & the drivers have more time to react to the sign message. These sheetings are High Intensity fluorescent with minimum useful life of 10 years & minimum reflection value as per ASTM D4956 is defined for yellow color. The acceptable types are 3, 4, 7 & 8.